Stage 3. Cavern inwash

At production casing opening out with OD102mm & OD114mm it’s necessary to notice that there should be some tubing used in the perforation process with beveled couplings because of the small annular gap of the liner. There were no problems either with opening out or with water jet treatment based on experience of working in horizontal wells.

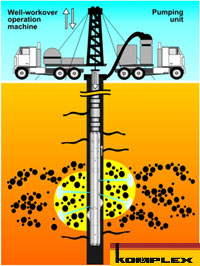

Fluid jet of the ejector washes out the cement sheath & adjacent formation under high pressure 15MPa, creates filtration channels with deep penetrability (>0,5m) & caverns in the nearwellbore zone. High penetrating ability of ejectors is provided by the technology of alternate creating of 2 adjacent filtration channels, eliminating the jet tightness phenomenon which considerably decreases the jet speed & depth of rock destruction.

Fluid jet of the ejector washes out the cement sheath & adjacent formation under high pressure 15MPa, creates filtration channels with deep penetrability (>0,5m) & caverns in the nearwellbore zone. High penetrating ability of ejectors is provided by the technology of alternate creating of 2 adjacent filtration channels, eliminating the jet tightness phenomenon which considerably decreases the jet speed & depth of rock destruction.

Ejectors orient the jet into the plane of cut slots downward at an angle 750 (two ejectors), also at an angle 900 (two ejectors), against the perforator axis. The run time of pointlike operation is 3-5 minutes & discretisation of descent to the bed floor is 180-200mm.

We recommend carrying out SHMP with chemical treatment of the nearwellbore zone through slatted Perforator for the purpose of a better renovation of fluid penetrating capability in the nearwellbore zone & its cleaning from mudding substances.

Itex —

Itex —