|

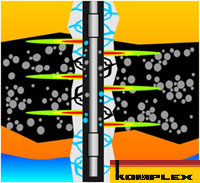

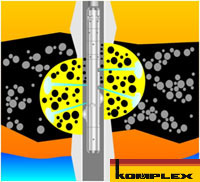

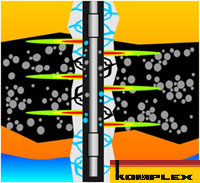

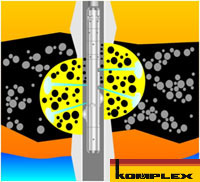

Comparison of key parametres slatted & jet perforation

|

| Configuration of formed channels in nearwellbore zone in slatted & jet perforation. |

|

Cumulative perforation has been used in world practice for more than 60 years. In spite of it cumulative perforation has some considerable disadvantages:

- It exerts destroying influence on the cement sheath.

- Lack of steering system (balancing system) brings to unsatisfactory holes.

- There is an opportunity that not all jet charges will be activated;

- Glass is formed because of the cumulative perforation flow action in the terrigenous rock. This results in the mudding of nearwellbore zone.

- The hole pattern in the production casing is not capable of including the maximum number of fluid conductive channels & well-drainage areas.

|

|

|

Hydro mechanical slatted perforation doesn’t have any disadvantages at all:

- This is an absolutely safe technology.

- There is no destruction of the cement sheath.

- HMSP creates an extensive completion area & spacious caverns.

- HMSP provides the best connectivity of the well & formation.

- HMSP simplifies the operations for production stimulation & reservoir recovery increase.

|

|

Itex —

Itex —